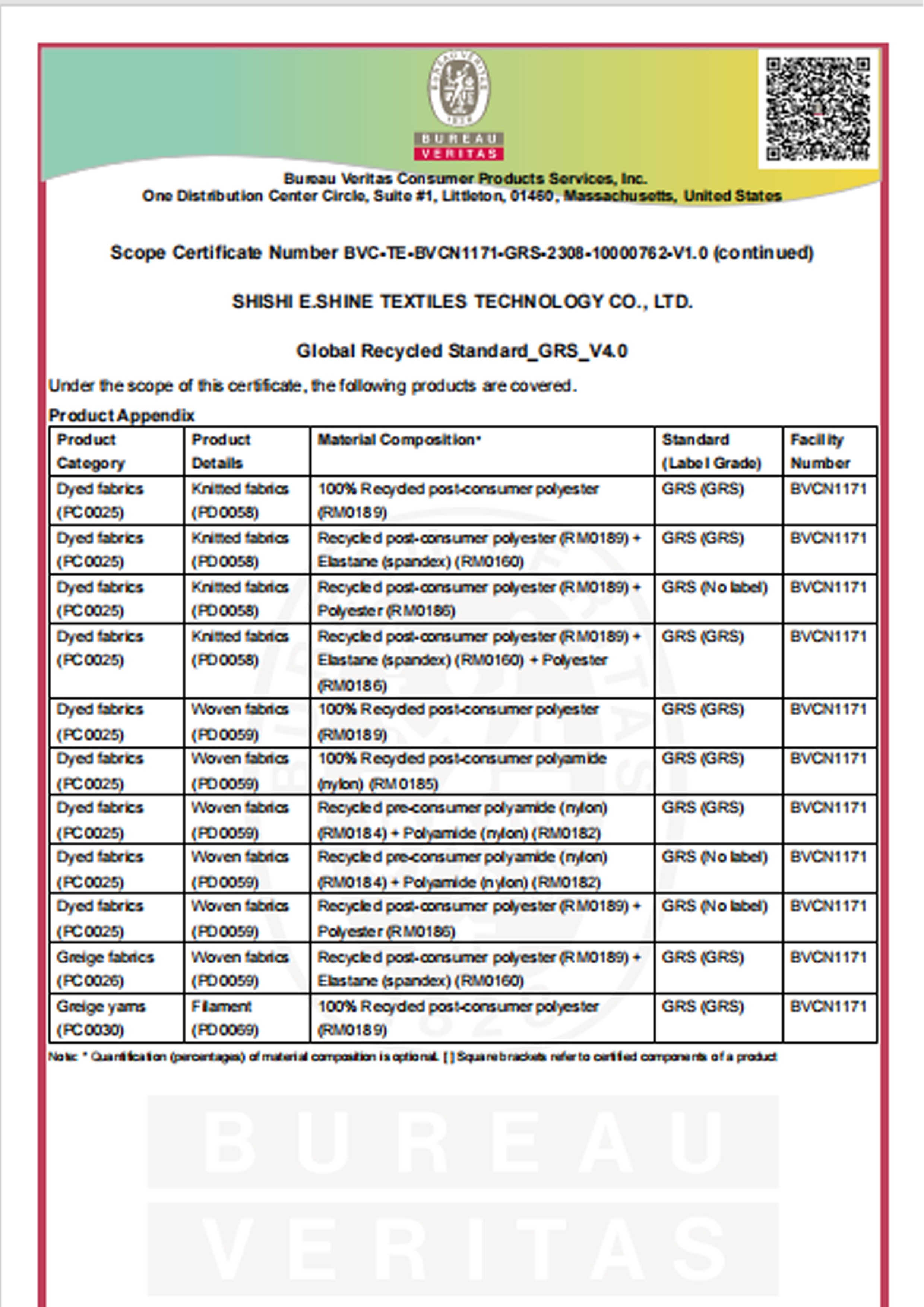

Certification

Workshop

Production Process

1. Raw Material Verification

For military uniform-specific fabrics (e.g., wear-resistant canvas, tear-resistant fiber cloth) and supporting components (metal fasteners, identification accessories, reinforced threads, etc.), conduct comprehensive verification of quality, specifications, and quantity. Ensure each batch of raw materials complies with military material procurement standards, eliminating material risks at the source.

2. CAD Pattern Design

Rely on professional CAD pattern-making software and follow military uniform pattern specifications (including precise parameters such as shoulder width, garment length, and sleeve shape) to generate 1:1 accurate paper patterns and structural design drawings that can be directly used in production. Ensure the dimensional error of subsequent cut pieces is ≤ 0.1cm to meet standardized production requirements.

3. Precision Cutting Process

Use a CNC cutting machine system to automatically cut fabrics in strict accordance with CAD design drawings. Conduct independent positioning and calibration for special-shaped cut pieces (e.g., pocket curves, shoulder joints) to ensure neat edges and uniform dimensions of each cut piece, meeting the regularity requirements of military uniforms.

4. Sewing & Reinforcement Technology

Assemble cut pieces using military-grade industrial sewing machines. Focus on high-stress critical areas such as shoulder seams, waistbands, and pocket joints, and apply high-density bartacking for reinforcement. This enhances the durability of uniforms, making them suitable for high-intensity usage scenarios of military apparel.

5. Semi-Finished Product Quality Inspection

Perform a one-by-one quality check on semi-finished uniforms that have not yet completed final assembly. Focus on identifying issues such as stitching deviations, misaligned joints, and inaccurate buttonhole positioning. Mark and repair defects on-site to prevent problems from flowing into subsequent processes and reduce rework costs.

6. Finished Product Sewing & Finalization

Complete finishing processes including pocket sewing, fixation of military insignias (badges/armbands), and installation of buttons/zippers. Strictly follow military uniform insignia attachment standards (e.g., insignia position deviation ≤ 0.5cm) to ensure the appearance details of uniforms meet regulatory requirements.

7. 100% Quality Audit for Finished Products

Implement 100% full inspection of all finished uniforms. Review each item against military uniform quality standards (including indicators such as fabric wear resistance, stitching fastness, wash dimensional stability, and color fastness). Return unqualified products directly for rework to prevent defective products from reaching downstream.

8. Steam Setting & Ironing

Use professional steam setting and ironing equipment to process uniforms in accordance with military attire neatness standards. Focus on smoothing wrinkles in key areas such as collars, cuffs, and trouser creases, ensuring uniforms have neat lines after shaping and meet the solemnity requirements of military occasions.

9. Protective Packaging

Use moisture-proof and dust-proof specialized packaging materials to individually package uniforms by order batch. Mark product models, quantities, and storage protection labels on the outer packaging to ensure no contamination or deformation during transportation and storage.

10. Pre-Shipment AQL Sampling Inspection

Based on the international AQL 2.5 sampling standard (i.e., allowable defective rate of batch products ≤ 2.5%), conduct a final quality review of uniforms to be shipped. Sampling inspection items cover appearance, dimensions, and process firmness. Only after all items pass the inspection can the goods be arranged for delivery.